- Introduction

- Improve Inventory Accuracy Using Inventory Management Software

- Improve Sales and Purchase Orders Using Inventory Management Software

- Inventory Management Software Help to Create

- Inventory Management Software Help to Create

- reduce time using Inventory Management system for Multi-location Inventory Management

Key Takeaways:

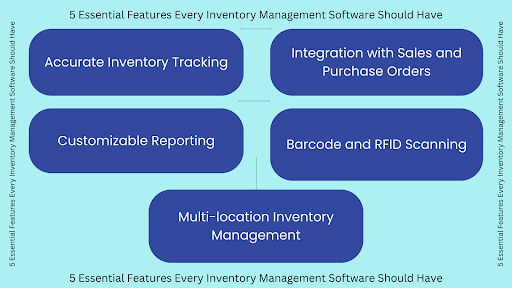

Inventory Management System has become one of the most important tasks for businesses selling manufactured products. And the number of businesses selling products is huge! Even though the needs of every business can be unique to its nature, it is safe to say that inventory management system is almost the same for every business. Hence, the requirement of certain features in an Inventory Management Software is more or less the same for almost all businesses.

Inventory Management Software is designed to help businesses manage their inventory levels and track inventory-related activities such as purchasing, warehousing, and sales. The inventory management software works by collecting data about each item in the inventory, including the quantity on hand, the location, and the cost. It also tracks inventory movements, such as goods received, items sold, and items transferred between warehouses. With this information, the inventory management software can generate reports and provide real-time inventory updates, helping businesses optimize their inventory levels, reduce waste, and avoid stockouts. The inventory management software can be integrated with other systems such as accounting and order management software to streamline operations and improve efficiency.

Improve Inventory Accuracy Using Inventory Management Software

Accurate inventory tracking is crucial for any business that manages a physical inventory. An inventory management system provides real-time visibility into inventory levels, enabling businesses to track stock levels, movement, and usage. With an inventory management system, businesses can eliminate guesswork and manual tracking methods, reducing the risk of stockouts and overstocking. By providing a centralized platform to monitor inventory levels, businesses can easily identify and reconcile discrepancies, minimizing the chances of inventory loss, theft, or damage. Additionally, accurate inventory tracking can help businesses make informed decisions regarding purchasing, production, and sales, leading to better inventory management tool and increased profitability. Overall, an inventory management system is an essential tool for businesses looking to streamline their operations and achieve accurate inventory tracking.

Improve Sales and Purchase Orders Using Inventory Management Software

Inventory management systems offer integration with sales and purchase orders, which streamlines the purchasing process by automating the creation of purchase orders and sending them to suppliers. With integration to sales orders, the inventory management system can also track which products are sold and adjust the inventory levels automatically, making it easier to keep accurate inventory records. This integration can reduce manual errors and enhance accuracy, resulting in improved customer satisfaction and increased efficiency. Furthermore, this integration allows for real-time tracking of the inventory status, including reorder points and lead times, which can help managers make informed purchasing decisions and avoid stockouts.

Inventory Management Software Help to Create

Customizable reporting is a crucial feature of inventory management software that enables businesses to generate detailed reports on various inventory-related data. This feature allows users to create custom reports that align with their business goals and requirements, such as sales performance, inventory levels, and product trends. With customizable reporting, businesses can quickly access the data they need to make informed decisions about their inventory, allowing them to optimize their operations and improve overall efficiency. Additionally, this feature enables businesses to monitor their inventory and identify any trends or patterns that require attention, such as slow-moving products or stockouts. Overall, customizable reporting is a valuable tool for businesses looking to gain greater visibility into their inventory and streamline their operations.

Inventory Management Software Help to Create

Barcode and RFID scanning is an important feature of an inventory management system that allows for more accurate and efficient tracking of inventory. With this feature, products can be assigned a unique barcode or RFID tag, which can be scanned using a handheld scanner or a mobile device. This allows for quick and easy tracking of inventory movements, from receiving new shipments to shipping out products to customers. Barcode and RFID scanning also eliminates the need for manual data entry, reducing the risk of errors and increasing efficiency. Additionally, the scanning data can be used to generate reports and analyze inventory trends, providing valuable insights to improve inventory management processes.

reduce time using Inventory Management system for Multi-location Inventory Management

Multi-location inventory management system is a crucial feature of any robust inventory management system. It allows businesses to keep track of their inventory across multiple locations in real-time. With this feature, businesses can easily transfer products from one location to another, allocate stock to specific locations based on demand, and ensure that all locations have the right amount of stock. Multi-location inventory management helps businesses minimize stockouts, prevent overstocking, and optimize their inventory levels to meet customer demand. Additionally, it provides a consolidated view of inventory levels across all locations, enabling businesses to make informed decisions about stock replenishment, ordering, and distribution.

Proper Inventory Management prevents businesses from taking uninformed decisions and helps them to save costs on production. Businesses selling manufactured products need to maintain a constant stock of the products. This helps them to meet the needs of the customers on time. However, problems like overstocking and understocking are common in these cases. This may lead to wastage of resources and unmet demands of the customers.

We’d Love To Hear From You!

Drive Business Growth with Nuraltech

Empower your sales, distribution & analytics with data-driven SaaS solutions.

Schedule a Demo